CAM Services

Galex offers comprehensive CAM services for PCB manufacturers, covering everything from Gerber files to panel output. We conduct rigorous design rule checks on every board to eliminate errors that could result in scrap. All features undergo a thorough violation check before panelization. With deep expertise, we manage even the most complex designs, including multi-layer boards (up to 40 layers) and advanced techniques such as gold fingers, via fill, blind & buried vias, back panel boards, and impedance control.

PRECAM

We take extra care in thoroughly examining the data provided by the customer, ensuring all requirements are clearly captured. Any inconsistencies in the files are carefully confirmed with the customer before proceeding with cleanup and further processing.

DESIGN RULE CHECKS

We carry out detailed Design Rule Checks on all boards to prevent any errors that could lead to scrap. Each feature is meticulously examined for violations before the board is panelized, ensuring top-quality output.

EDIT

Any violations found during the DRC process will be assessed and corrected to ensure manufacturing compatibility. Any unresolved issues will be flagged and communicated to the customer, highlighting critical concerns. In these cases, either revised files will be requested or extra attention will be given to address the issues.

ARRAY

An array is like a blueprint, where a single board is repeated to create a larger connected panel. Also known as 'step and repeat,' it's commonly referred to as a customer panel, stepped-out, palletized rout, or retain.

PANELIZATION

Experience precision like never before! We tailor your panelization setup to match your factory standards, expertly arranging boards on one large panel through the step-and-repeat method. From custom coupon placement to adding venting patterns, mounting holes, and fiducials, we ensure every detail is optimized for perfect performance.

Drill / ROUT PROG

Custom-tailored NC files are created for your Drill & Rout machines, fine-tuned to your exact needs. We personalize every detail, including the File Header, Tool Change, Tool Finish, Step & Repeat Start/End, and End of File, ensuring hhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhhh flawless execution and maximum efficiency.

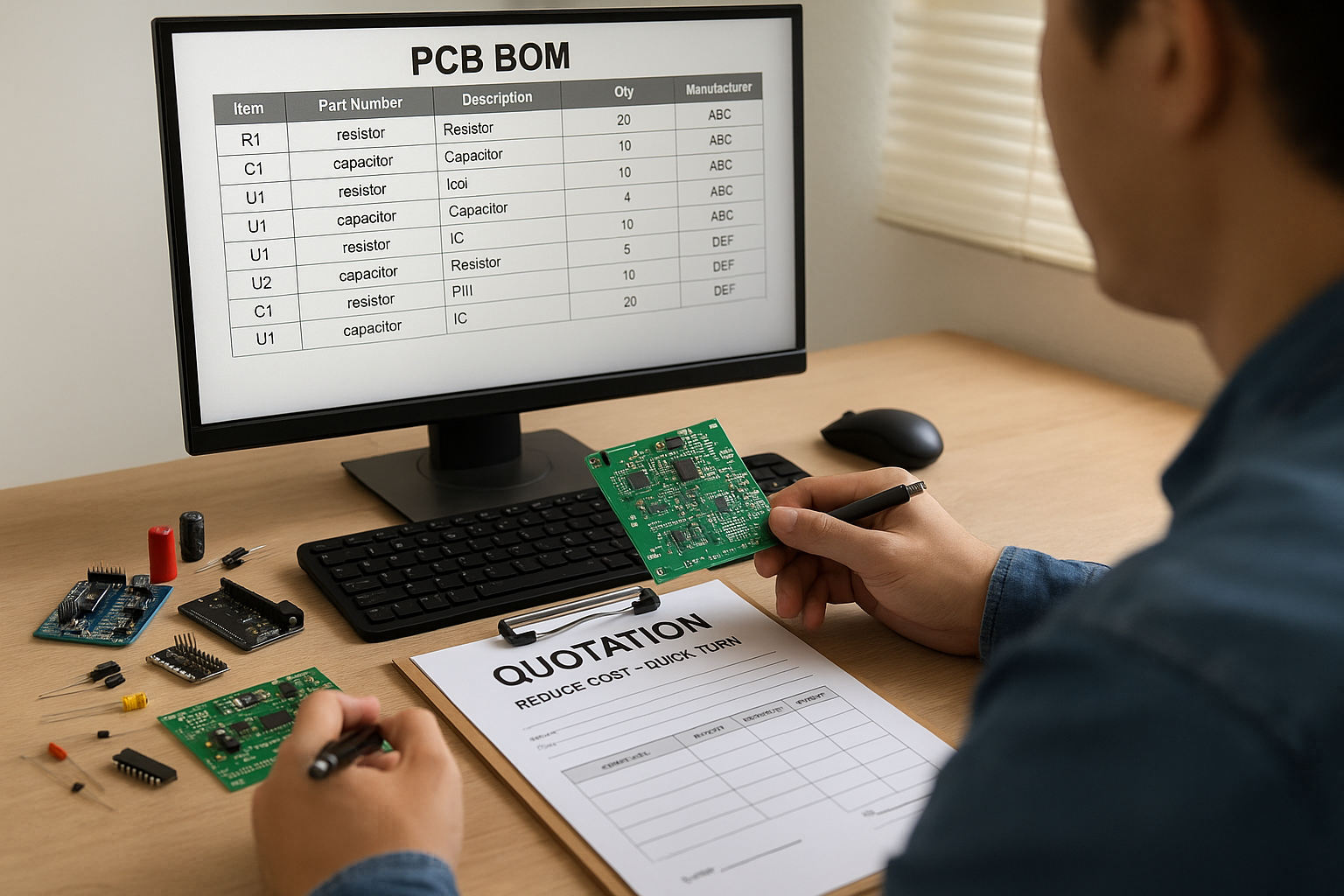

Quotation

We offer quick and precise PCB quotations tailored to your specific requirements. By analyzing your design files—such as Gerber data, layer count, board size, and material preferences—we ensure that every aspect of your project is considered. Our team reviews the technical details to avoid any production issues and provides competitive pricing based on quantity, complexity, and delivery timelines. Our transparent and hassle-free quotation process helps you plan better and move faster. We make the process smoother by standardizing data extraction, identifying red flags early, and providing ready-to-use summaries for fast quote generation. Our goal is to make your quoting process faster, clearer, and more reliable..

CAM Quote

Assembly Quote

Impedance Calculation / Stackup Build