Why Staying Ahead in PCB Technology Is Critical

The PCB industry is evolving rapidly, demanding constant innovation and up-to-date expertise. One of our key customers specializes in advanced designs with complex special processes, and most of their manufactured boards fall into this challenging category. Staying current is essential to meet these critical requirements and maintain high standards.

Expertise That Builds Trust and Drives Quality

Quality output is the foundation of a trustworthy relationship. At GALEX, we invest heavily in training our engineers not just to follow routine steps but to understand special processes deeply. This empowers them to make the right decisions in critical situations and consistently deliver work that inspires confidence.

A Structured Process That Ensures Consistency

To maintain broad expertise, we rotate engineers through special process assignments regularly, ensuring all team members can handle complex jobs. Every special process job undergoes a strict quality check. Weekly team leader meetings clarify doubts and reinforce knowledge, while updated customer checklists and libraries—refined through continuous feedback—keep our process flow sharp and reliable.

Proven Results That Win Repeat Business

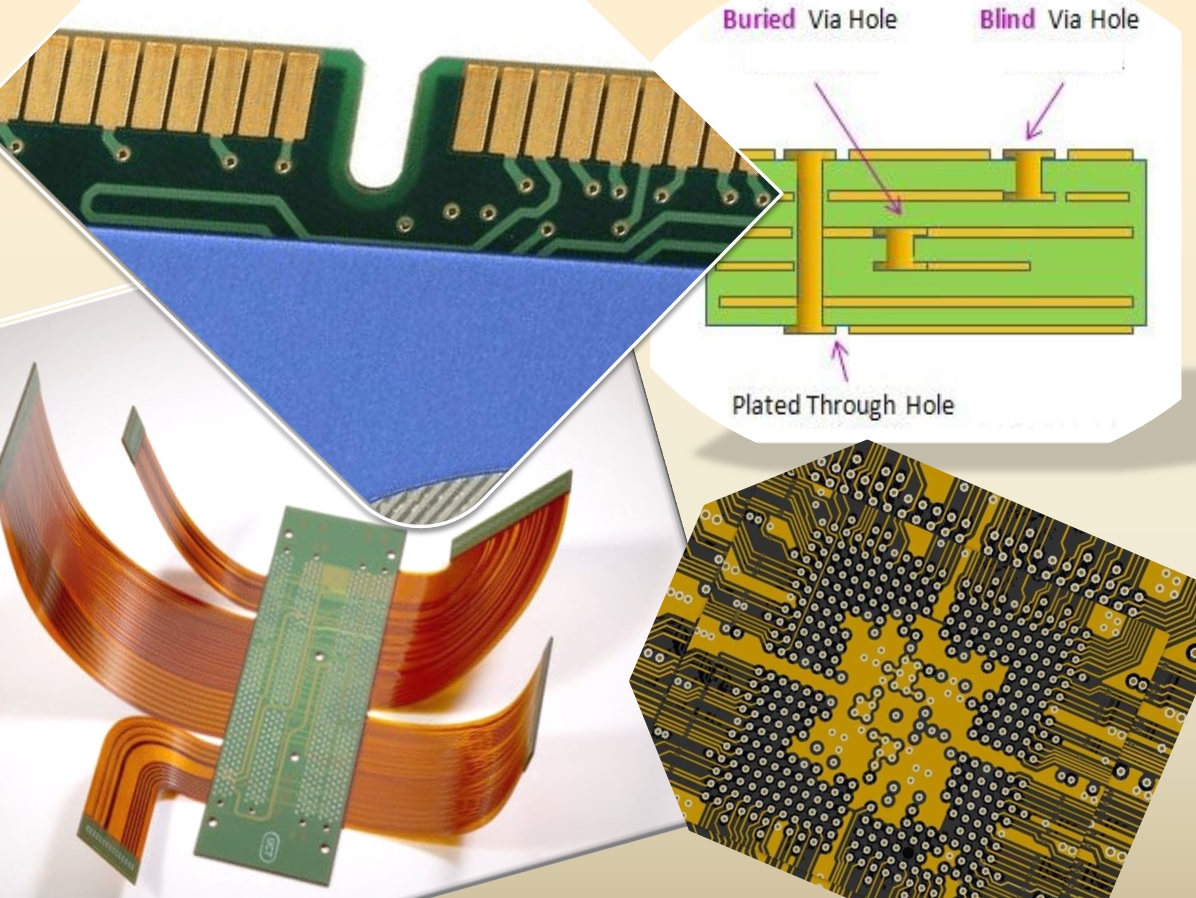

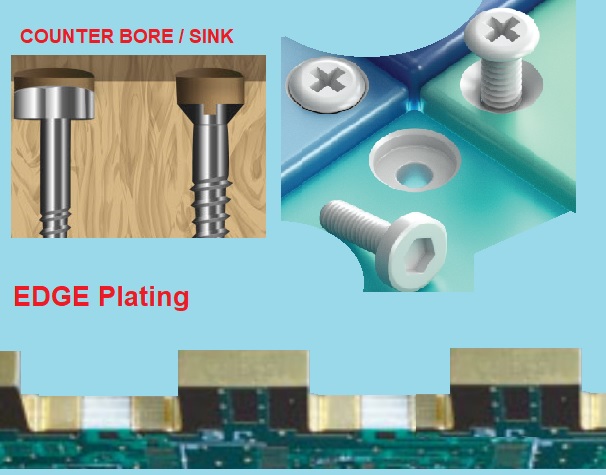

Thanks to our well-designed internal processes and committed team, GALEX has become a trusted resource for specialized PCB manufacturing support. Recently, we successfully completed a highly complex project featuring blind, buried, and stacked laser vias, cavities, and plated edges. The customer was delighted with our CAM quality and has since continued sending similar challenging jobs regularly.